Project status update (with nice pictures).

Received most of hardware orders (except cables).

PCBs (oscillator and shield):

Received from DirtyPCBs - 15 oscillator PCBs and 10 PCBs boards just because 1 and 15 (1 and 10) cost is the same $20.

Diligent Cora Z7-10 FPGA board with PMods I2S2(line in/out) and AMP3(headphones):

Everything together (gray thing is for mounting of coils):

Now I have to wind coils, solder oscillators and shield.

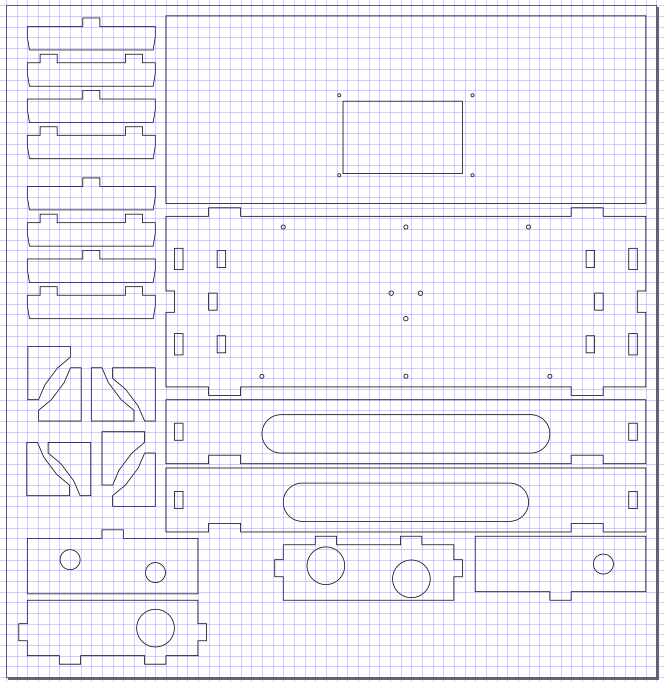

Cabinet plywood laser cut design - mostly finalized, going to order manufacturing soon.

Software part update:

- AXI4Lite Theremin Sensor Controller verilog code is mostly ready - to be tested on hardware with real oscillators and antennas.

-Audio IO IP in verilog - I2S (two stereo outputs and one stereo input 48KHz 24bit) and I2C (for headphones volume control) are implemented - to be tested on hardware.

- Making simple triangle tone generator for end-to-end testing (pitch+volume from sensor -> tone generator -> audio output).

- Display controller IP: I have written HDMI OUT adapter with DMA for Zybo board - can be easy ported to parallel RGB interface.

- Resistive touch screen controller IP - to be done.